Energy

Matrix delivers engineered composites, protective coatings, and subsea buoyancy systems that are designed to meet the extreme demands of energy infrastructure. Whether installed on platforms, pipelines, or LNG systems, our solutions extend asset life, reduce downtime, and perform reliably in harsh offshore, onshore, and subsea environments.

Energy

Matrix delivers engineered composites, protective coatings, and subsea buoyancy systems that are designed to meet the extreme demands of energy infrastructure. Whether installed on platforms, pipelines, or LNG systems, our solutions extend asset life, reduce downtime, and perform reliably in harsh offshore, onshore, and subsea environments.

INDUSTRY CHALLENGES WE SOLVE

Energy infrastructure – from surface to seabed – is exposed to corrosion, fatigue, cryogenic conditions and chemical degradation. As the industry transitions to new fuels and deeper environments, demand for durable, high-performance materials grows. Matrix provides engineered solutions that protect critical assets and maintain performance under the harshest conditions.

Marine Corrosion

Offshore and coastal infrastructure is vulnerable to saltwater exposure. Matrix coatings and composites reduce corrosion and extend service life.

Structural Fatigue

Constant vibration, pressure, and temperature changes degrade structural integrity. Our composites provide strength and help keep assets operational.

Cryogenic and Chemical Exposure

LNG infrastructure faces extreme demands. Matrix materials resist cryogenic temperatures and chemical attack.

Maintaining Subsea Buoyancy

Risers, flowlines, and subsea structures depend on stable buoyancy. Our syntactic foams are depth-rated and field proven.

Asset Downtime

Unexpected failures can be costly. Matrix offers repair systems and services to restore integrity and resume operations quickly.

Energy Transition

Emerging energy systems require high-performance materials. Our solutions enhance durability and operational efficiency across transitional infrastructure.

INDUSTRY CHALLENGES WE SOLVE

Energy infrastructure – from surface to seabed – is exposed to corrosion, fatigue, cryogenic conditions and chemical degradation. As the industry transitions to new fuels and deeper environments, demand for durable, high-performance materials grows. Matrix provides engineered solutions that protect critical assets and maintain performance under the harshest conditions.

Marine corrosion

Offshore and coastal infrastructure is vulnerable to saltwater exposure. Matrix coatings and composites reduce corrosion and extend service life.

Structural fatigue

Constant vibration, pressure, and temperature changes degrade structural integrity. Our composites provide strength and help keep assets operational.

Cryogenic and chemical exposure

LNG infrastructure faces extreme demands. Matrix materials resist cryogenic temperatures and chemical attack.

Marine corrosion

Offshore and coastal infrastructure is vulnerable to saltwater exposure. Matrix coatings and composites reduce corrosion and extend service life.

Structural fatigue

Constant vibration, pressure, and temperature changes degrade structural integrity. Our composites provide strength and help keep assets operational.

Cryogenic and chemical exposure

LNG infrastructure faces extreme demands. Matrix materials resist cryogenic temperatures and chemical attack.

Maintaining subsea buoyancy

Risers, flowlines, and subsea structures depend on stable buoyancy. Our syntactic foams are depth-rated and field proven.

Asset downtime

Unexpected failures can be costly. Matrix offers repair systems and services to restore integrity and resume operations quickly.

Energy transition

Emerging energy systems require high-performance materials. Our solutions enhance durability and operational efficiency across transitional infrastructure.

Maintaining subsea buoyancy

Risers, flowlines, and subsea structures depend on stable buoyancy. Our syntactic foams are depth-rated and field proven.

Asset downtime

Unexpected failures can be costly. Matrix offers repair systems and services to restore integrity and resume operations quickly.

Energy transition

Emerging energy systems require high-performance materials. Our solutions enhance durability and operational efficiency across transitional infrastructure.

COMPOSITES THAT DELIVER. STRONGER, SAFER, CORROSION-FREE

Years Delivering Energy Solutions

Corrosion-Resistance Materials

BUOYANCY MODULES DELIVERED

TRAINED APPLICATORS

COMPOSITES THAT DELIVER. STRONGER, SAFER, CORROSION-FREE

Years Delivering Energy Solutions

Corrosion - Resistance Materials

BUOYANCY MODULES DELIVERED

TRAINED APPLICATORS

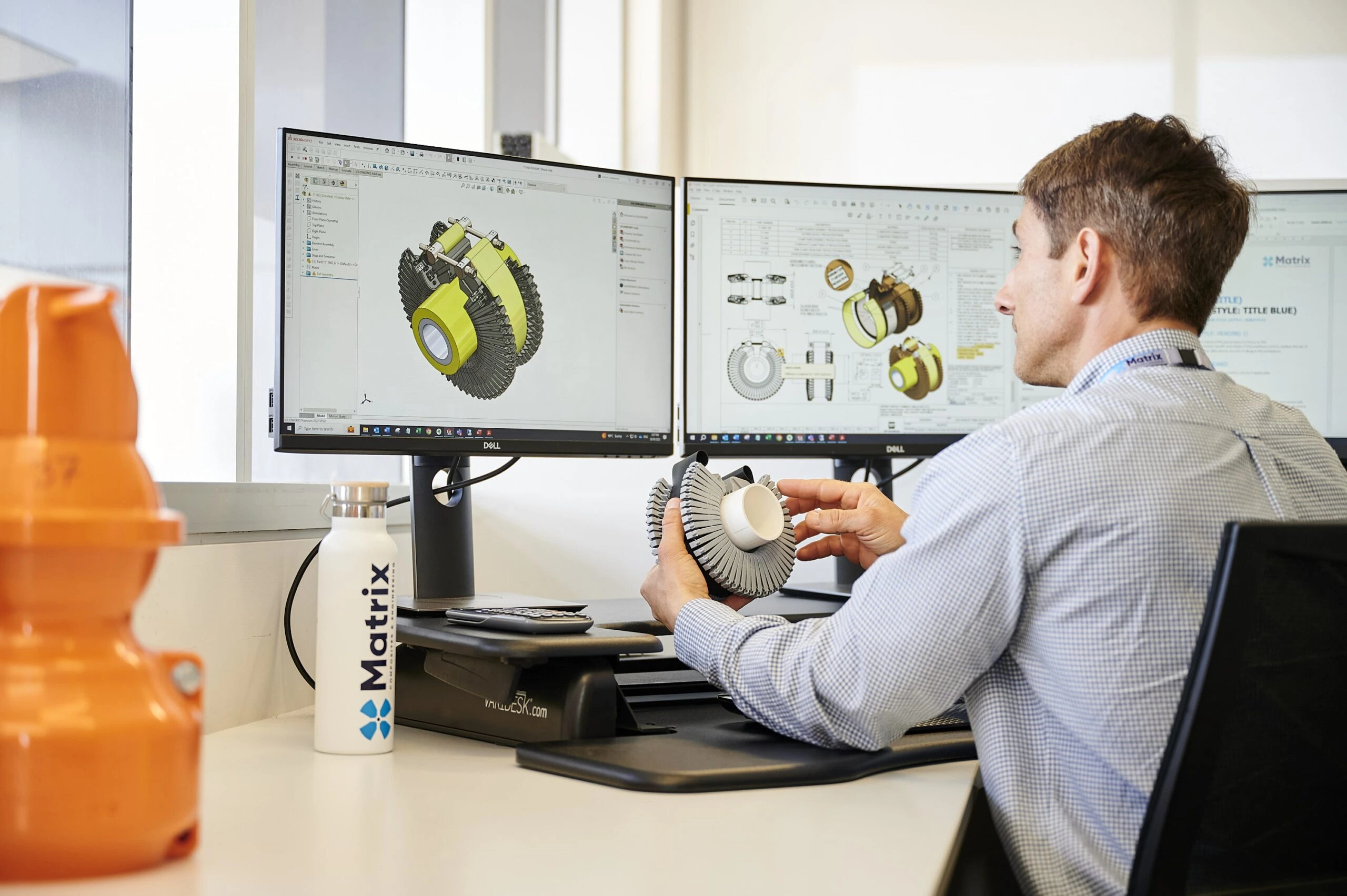

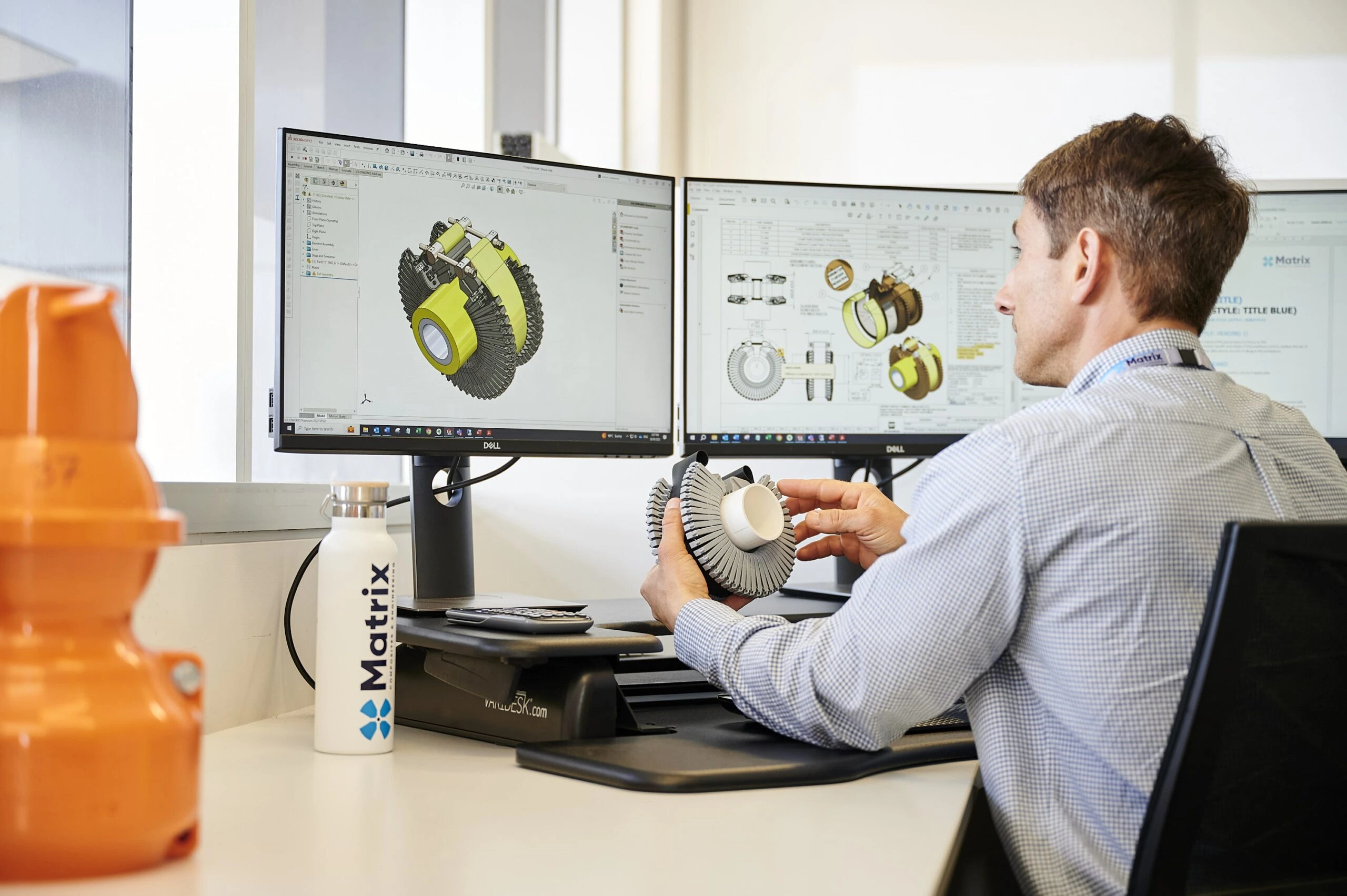

OUR CAPABILITIES IN ENERGY

Built for the harshest operating environments, our composites and polymer solutions are supported by fully integrated, end-to-end in-house capabilities:

OUR CAPABILITIES IN ENERGY

Built for the harshest operating environments, our composites and polymer solutions are supported by fully integrated, end-to-end in-house capabilities:

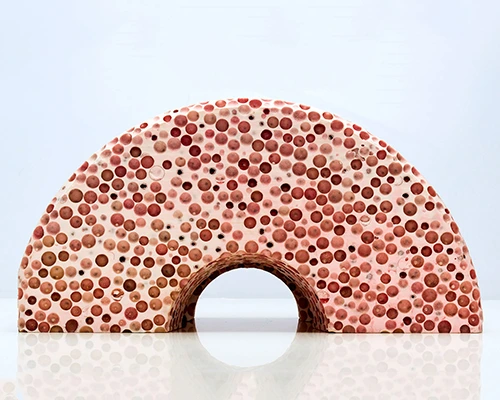

OUR ENERGY TECHNOLOGIES

From lightweight syntactic foams to corrosion-resistant coatings, Matrix technologies are purpose-built to meet the performance requirements of the energy sector.

OUR ENERGY TECHNOLOGIES

From lightweight syntactic foams to corrosion-resistant coatings, Matrix technologies are purpose-built to meet the performance requirements of the energy sector.

OUR ENERGY PRODUCTS & SERVICES

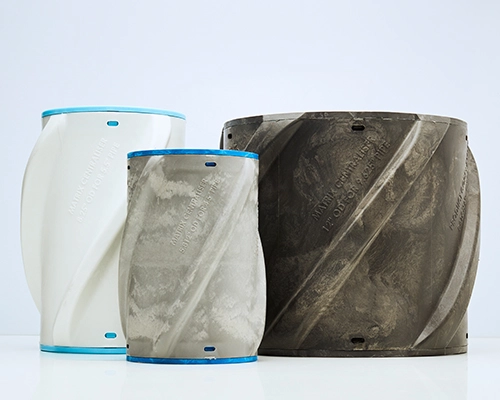

Distributed Buoyancy

Manufactured at the world’s largest syntactic foam facility for flexibles, umbilicals, and flowlines.

Drill Riser Buoyancy

High-strength syntactic foam modules reduce load and increase stability in deepwater drilling.

UUV Buoyancy

Integrated syntactic foam monocoque structures enable scalable, cost-effective mass production.

Matrix Drag and VIV Suppression

Hydrodynamic strakes and suppression systems reduce drag and vibration on subsea pipelines and structures.

Matrix Subsea Testing Centre

The Southern Hemisphere’s largest subsea test centre and Australia’s only common user hyperbaric facility.

Buoyancy Repair and Refurbishment

Inspection, repair, and recertification to extend the operational life of buoyancy modules.

OUR ENERGY PRODUCTS & SERVICES

Distributed Buoyancy

Manufactured at the world’s largest syntactic foam facility for flexibles, umbilicals, and flowlines.

Drill Riser Buoyancy

High-strength syntactic foam modules reduce load and increase stability in deepwater drilling.

UUV Buoyancy

Integrated syntactic foam monocoque structures enable scalable, cost-effective mass production.

Matrix Drag and VIV Suppression

Hydrodynamic strakes and suppression systems reduce drag and vibration on subsea pipelines and structures.

Matrix Subsea Testing Centre

The Southern Hemisphere’s largest subsea test centre and Australia’s only common user hyperbaric facility.

Buoyancy Repair and Refurbishment

Inspection, repair, and recertification to extend the operational life of buoyancy modules.

OUR ENERGY PRODUCTS & SERVICES

Distributed Buoyancy

Manufactured at the world’s largest syntactic foam facility for flexibles, umbilicals, and flowlines.

Drill Riser Buoyancy

High-strength syntactic foam modules reduce load and increase stability in deepwater drilling.

UUV Buoyancy

Integrated syntactic foam monocoque structures enable scalable, cost-effective mass production.

Matrix Drag and VIV Suppression

Hydrodynamic strakes and suppression systems reduce drag and vibration on subsea pipelines and structures.

Matrix Subsea Testing Centre

The Southern Hemisphere’s largest subsea test centre and Australia’s only common user hyperbaric facility.

Buoyancy Repair and Refurbishment

Inspection, repair, and recertification to extend the operational life of buoyancy modules.

WHY CHOOSE MATRIX FOR ENERGY

- The world’s largest syntactic foam manufacturing facility.

- The Southern Hemisphere’s largest subsea test centre.

- Australia’s only common user hyperbaric testing facility.

From deepwater drilling to LNG infrastructure. Matrix helps extend asset life, reduce downtime, and improve safety across the energy supply chain.

WHY CHOOSE MATRIX FOR ENERGY

With over 25 years of experience, Matrix is a trusted partner to leading energy companies worldwide. All materials and products are developed and manufactured at our Henderson facility in Western Australia, home to:

- The world’s largest syntactic foam manufacturing facility.

- The Southern Hemisphere’s largest subsea test centre.

- Australia’s only common user hyperbaric testing facility.

From deepwater drilling to LNG infrastructure. Matrix helps extend asset life, reduce downtime, and improve safety across the energy supply chain.

WHY CHOOSE MATRIX FOR ENERGY

With over 25 years of experience, Matrix is a trusted partner to leading energy companies worldwide. All materials and products are developed and manufactured at our Henderson facility in Western Australia, home to:

- The world’s largest syntactic foam manufacturing facility.

- The Southern Hemisphere’s largest subsea test centre.

- Australia’s only common user hyperbaric testing facility.

From deepwater drilling to LNG infrastructure. Matrix helps extend asset life, reduce downtime, and improve safety across the energy supply chain.

LET’S TALK ENERGY SOLUTIONS

Need structural reinforcement, subsea buoyancy, or corrosion protection? Connect with our team to Discover how Matrix can support your next energy project.

LET’S TALK ENERGY SOLUTIONS

Need structural reinforcement, subsea buoyancy, or corrosion protection? Connect with our team to Discover how Matrix can support your next energy project.