Advanced Manufacturing

Making the impossible possible

At Matrix Composites & Engineering, advanced manufacturing is more than automation. It is how we deliver world-class composite solutions that are lighter, smarter, stronger, and ready for the most demanding applications. From ideation to commercialisation, we integrate cutting-edge processes, materials science, and engineering precision to stay globally competitive and deliver value to our customers and the broader Australian economy.

Advanced Manufacturing

Making the impossible possible

At Matrix Composites & Engineering, advanced manufacturing is more than automation. It is how we deliver world-class composite solutions that are lighter, smarter, stronger, and ready for the most demanding applications. From ideation to commercialisation, we integrate cutting-edge processes, materials science, and engineering precision to stay globally competitive and deliver value to our customers and the broader Australian economy.

WORLD-CLASS CAPABILITY, BUILT TO DELIVER AT SCALE

Our advanced manufacturing capability is certified to ISO 9001 (quality), ISO 14001 (environmental management), and ISO 45001 (health and safety), reflecting our commitment to excellence and continuous improvement. It’s this discipline, coupled with innovation, that enables us to solve complex challenges with consistency and reliability.

With over $1 billion in Australian-made composite goods exported to the global energy sector, Matrix has proven its ability to compete on the world stage. Our technology group works closely with customers to tailor solutions that maximise performance, reduce weight, and withstand the harshest environments, from subsea and offshore applications to defence, infrastructure, and renewables.

The integration of in-house testing, R&D, and materials development ensures every product we manufacture is validated and production ready. Whether it is a specialised resin system, impact-resistant thermoplastic, or lightweight structural component, we bring together design, process, and performance to deliver smarter results.

OUR ADVANCED MANUFACTURING CAPABILITIES

High-volume Composite Production

Australia’s largest composite facility, built to deliver components at scale.

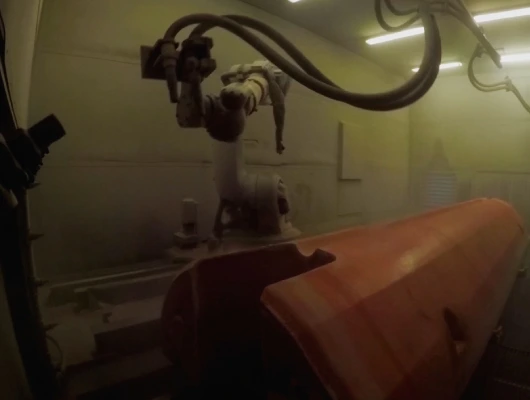

Automation and Process Control

SCADA systems, robotics, and automated chemical processing ensure consistency and efficiency

LEAN and One-piece Flow Manufacturing

Flexible, streamlined operations that reduce waste and improve responsiveness.

Certified Systems and Compliance

Operates to ISO 9001, 14001, and 45001 standards for quality, environment, and safety.

Integrated Development and Testing

R&D, materials development, and testing are embedded to accelerate manufacturing readiness.

Global Delivery and Export Scale

Over $1B in exports delivered worldwide, with infrastructure to support international delivery.

SUBSCRIBE

Subscribe

"*" indicates required fields