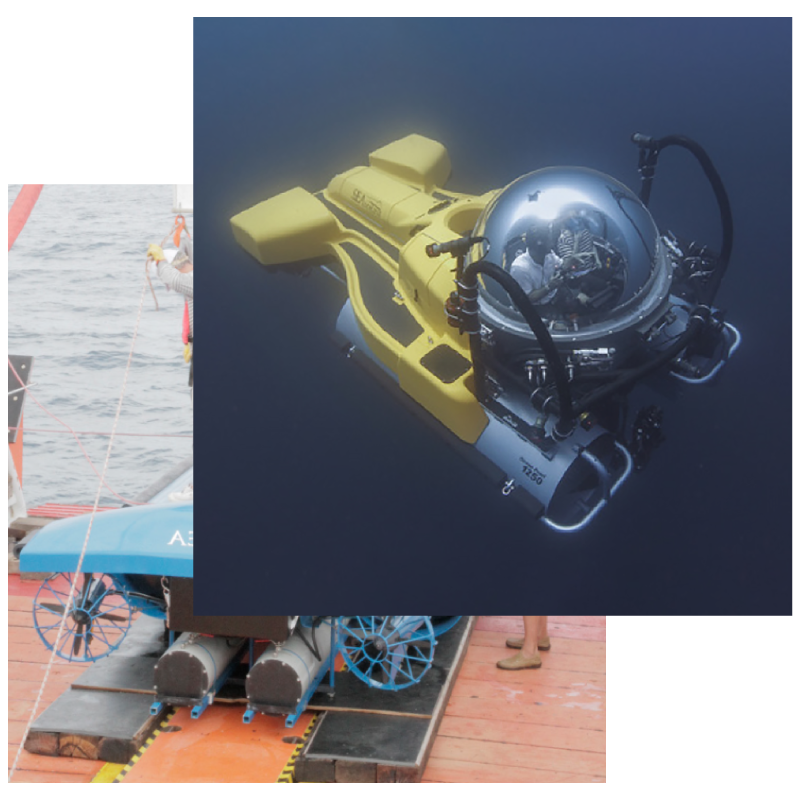

TESTING: HYDROSTATIC TESTING: MANNED SUBMARINE SPHERE

Background

The Matrix hydro testing facility allows testing of a wide range of products from large energy exploration support components and defence force equipment, down to the smallest of subsea electrical connectors.

It contains some of the world’s largest and deepest chambers that incorporate state of the art algorithms to precisely control pressure and temperature.

Client

International oil and gas producer

Time period

2017

Product

Matrix Hydro Testing Facilities, Henderson WA

Project location

Perth, WA

METHOD

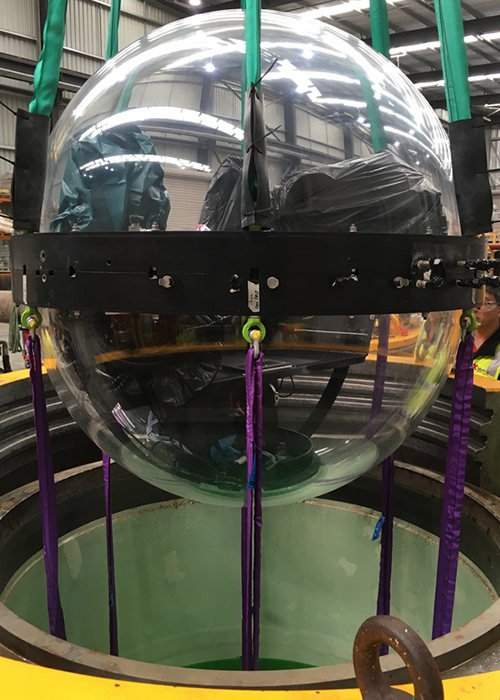

This test involved conducting a series of hydrostatic pressure cycles on the sphere according to the ABS standard 0007/2017 “Rules For Building And Classing Underwater Vehicles, Systems And Hyperbaric Facilities”.

The testing procedure was particularly challenging:

- The sphere could not be subjected to any excessive loading or movement during testing and lifting operations. With only 20mm clearance between the sphere and the chamber there was a significant risk of damage if the lifting configuration was not correctly designed.

- The chamber needed to be maintained to a tight temperature range of ~ +/-2.5 degrees Celsius throughout all the test cycles otherwise it would be invalid.

OUTCOME

The hydrostatic chamber maintained the required pressure / temperature profile and upon removal from the chamber no leakage was observed. The temperature was very stable holding within +/-1 degree for the duration of the test. The lifting configuration worked perfectly in protecting the sphere from having any contact with the chamber wall.