Infrastructure

Infrastructure

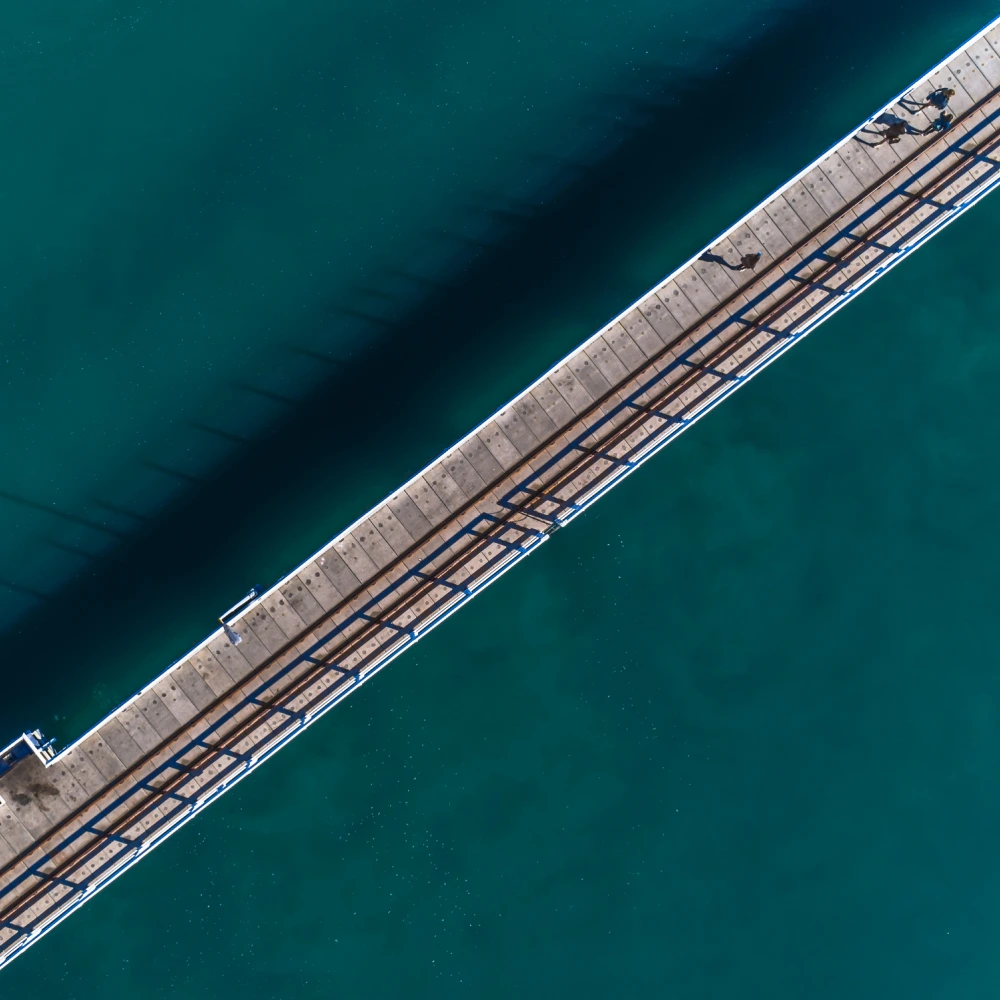

Matrix supports marine infrastructure projects with durable composite, polymer and protective coating solutions engineered for harsh coastal and subsea environments. From jetties and pontoons to submerged structures and pipelines, our corrosion-resistant materials reduce maintenance, improve safety, and extend service life in marine applications.

INDUSTRY CHALLENGES WE SOLVE

Saltwater Corrosion

Constant saltwater exposure leads to rapid degradation. Matrix rotolined materials, composite materials and protective coatings offer superior long-term protection.

Structural Wear and Fatigue

Pontoons, fenders, and piles endure repeated mechanical stress. Our materials resist fatigue and maintain strength under cyclical loading.

Subsea Installation Challenges

Matrix syntactic foams and buoyancy systems enable safe handling and installation of subsea infrastructure.

Coastal Erosion and Impact

Matrix elastomers and composites provide protective barriers and energy absorption in high-impact zones.

Maintenance and Lifecycle Cost

Traditional materials often require frequent inspection and repair. Matrix’s corrosion-free solutions and long-life coatings reduce maintenance burdens over decades.

Design Flexibility

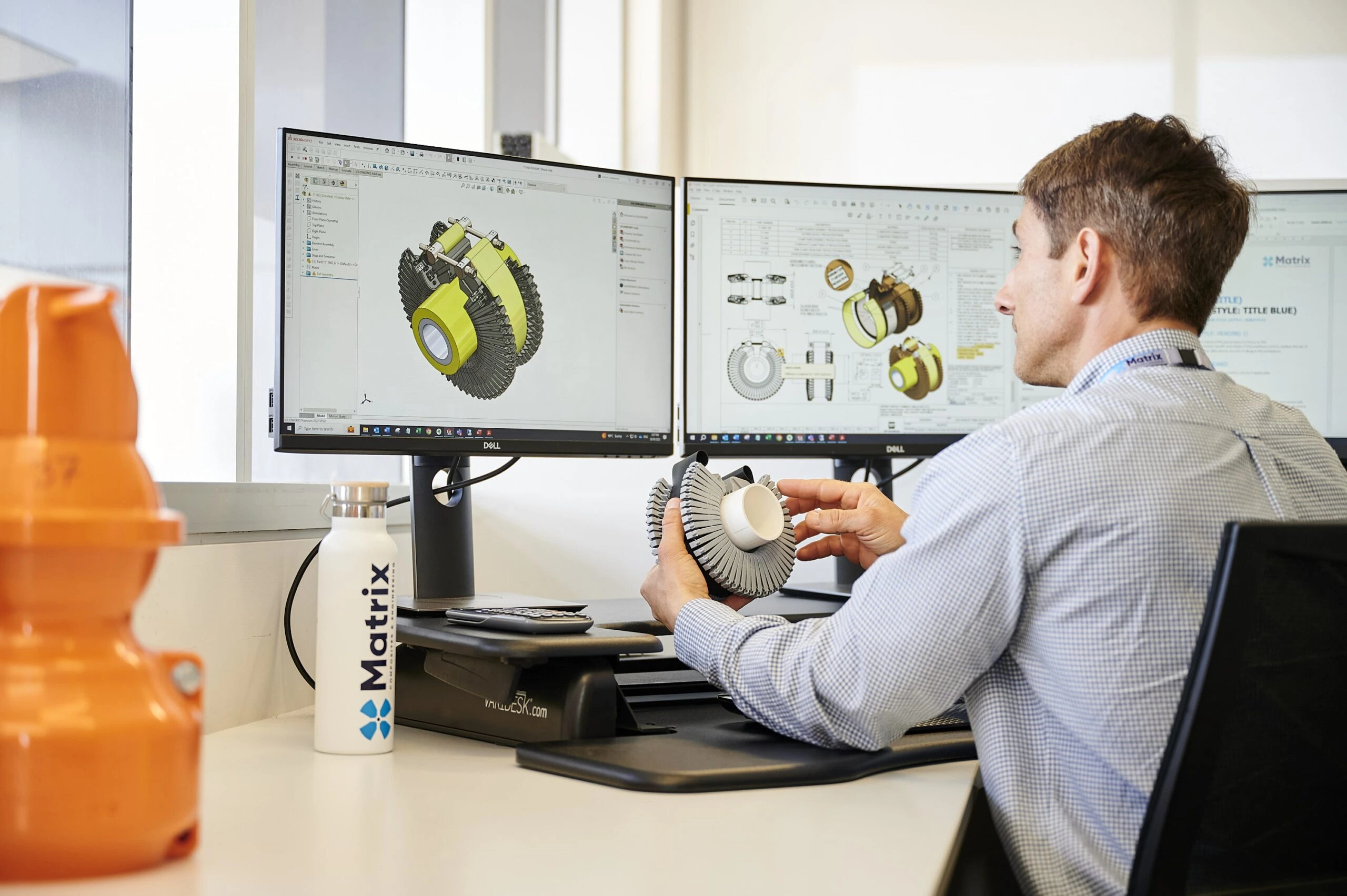

Marine assets require adaptable materials. Matrix advanced manufacturing supports complex shapes and integration with existing infrastructure systems.

INDUSTRY CHALLENGES WE SOLVE

Saltwater Corrosion

Constant saltwater exposure leads to rapid degradation. Matrix rotolined materials, composite materials and protective coatings offer superior long-term protection.

Structural Wear and Fatigue

Pontoons, fenders, and piles endure repeated mechanical stress. Our materials resist fatigue and maintain strength under cyclical loading.

Subsea Installation Challenges

Matrix syntactic foams and buoyancy systems enable safe handling and installation of subsea infrastructure.

Coastal Erosion and Impact

Matrix elastomers and composites provide protective barriers and energy absorption in high-impact zones.

Maintenance and Lifecycle Cost

Traditional materials often require frequent inspection and repair. Matrix’s corrosion-free solutions and long-life coatings reduce maintenance burdens over decades.

Design Flexibility

Marine assets require adaptable materials. Matrix advanced manufacturing supports complex shapes and integration with existing infrastructure systems.

INDUSTRY CHALLENGES WE SOLVE

Saltwater Corrosion

Constant saltwater exposure leads to rapid degradation. Matrix rotolined materials, composite materials and protective coatings offer superior long-term protection.

Structural Wear and Fatigue

Pontoons, fenders, and piles endure repeated mechanical stress. Our materials resist fatigue and maintain strength under cyclical loading.

Subsea Installation Challenges

Matrix syntactic foams and buoyancy systems enable safe handling and installation of subsea infrastructure.

Coastal Erosion and Impact

Matrix elastomers and composites provide protective barriers and energy absorption in high-impact zones.

Maintenance and Lifecycle Cost

Traditional materials often require frequent inspection and repair. Matrix’s corrosion-free solutions and long-life coatings reduce maintenance burdens over decades.

Design Flexibility

Marine assets require adaptable materials. Matrix advanced manufacturing supports complex shapes and integration with existing infrastructure systems.

MATERIALS BUILT FOR THE WATER. LIGHTER, STRONGER, SAFER AND CORROSION FREE.

REDUCTION IN MAINTENANCE COSTS

CORROSION-RESISTANT MATERIALS

TRAINED HUMIDUR APPLICATORS

YEARS MATERIALS DEVELOPMENT SPECIALIST

MATERIALS BUILT FOR THE WATER. LIGHTER, STRONGER, SAFER AND CORROSION FREE.

REDUCTION IN MAINTENANCE COSTS

CORROSION-RESISTANT MATERIALS

TRAINED HUMIDUR APPLICATORS

YEARS MATERIALS DEVELOPMENT SPECIALIST

OUR CAPABILITIES IN MARINE INFRASTRUCTURE

From jetties to subsea systems, Matrix offers complete support from material design through to on-site delivery:

OUR CAPABILITIES IN MARINE INFRASTRUCTURE

From jetties to subsea systems, Matrix offers complete support from material design through to on-site delivery:

OUR CAPABILITIES IN MARINE INFRASTRUCTURE

From jetties to subsea systems, Matrix offers complete support from material design through to on-site delivery:

OUR MARINE INFRASTRUCTURE TECHNOLOGIES

Matrix technologies are designed to withstand the mechanical, thermal, and chemical demands of marine environments:

OUR MARINE INFRASTRUCTURE TECHNOLOGIES

Matrix technologies are designed to withstand the mechanical, thermal, and chemical demands of marine environments:

OUR MARINE INFRASTRUCTURE TECHNOLOGIES

Matrix technologies are designed to withstand the mechanical, thermal, and chemical demands of marine environments:

OUR MARINE PRODUCTS & SERVICES

Matrix MarineShield™

Wraparound corrosion protection system for pipelines, risers, and piles in harsh marine environments

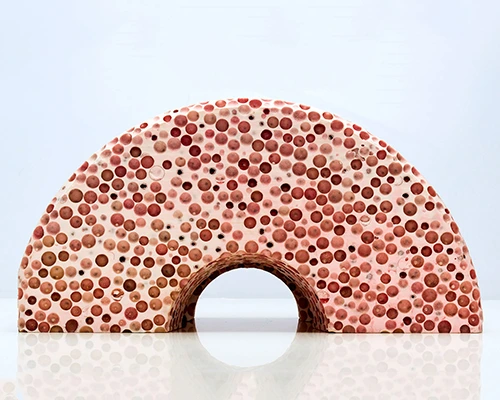

Distributed Buoyancy

Lightweight, depth-rated syntactic foam modules for dynamic cables, umbilicals, and flowlines

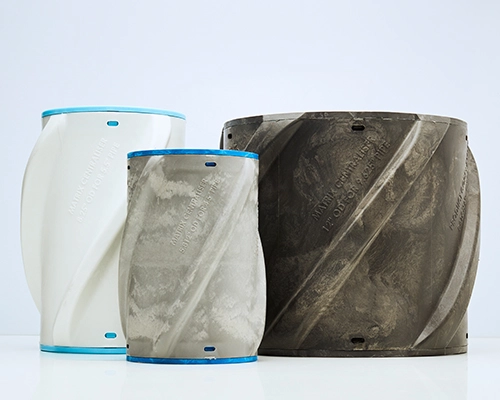

Installation Buoyancy

Engineered buoyancy aids that support safe lifting, deployment, and positioning of subsea infrastructure

Drill Riser Buoyancy

High-strength syntactic foam modules that reduce load and improve stability in deepwater drilling

Matrix Drag & VIV Suppression

Hydrodynamic strakes and fairings that reduce vortex-induced vibration and drag on subsea structures

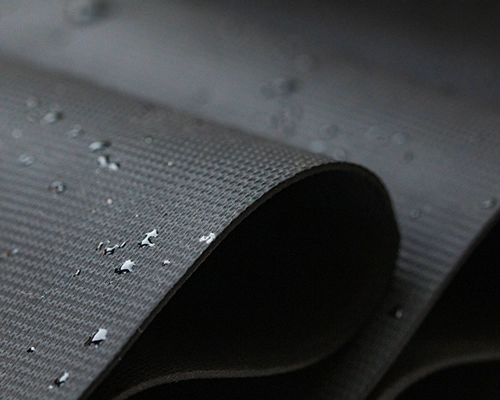

Protective Coatings (Humidur® FP)

Long-life, certified anti-corrosion coatings suitable for potable water and marine infrastructure applications

OUR MARINE PRODUCTS & SERVICES

Matrix MarineShield™

Wraparound corrosion protection system for pipelines, risers, and piles in harsh marine environments

Distributed Buoyancy

Lightweight, depth-rated syntactic foam modules for dynamic cables, umbilicals, and flowlines

Installation Buoyancy

Engineered buoyancy aids that support safe lifting, deployment, and positioning of subsea infrastructure

Drill Riser Buoyancy

High-strength syntactic foam modules that reduce load and improve stability in deepwater drilling

Matrix Drag & VIV Suppression

Hydrodynamic strakes and fairings that reduce vortex-induced vibration and drag on subsea structures

Protective Coatings (Humidur® FP)

Long-life, certified anti-corrosion coatings suitable for potable water and marine infrastructure applications

OUR MARINE PRODUCTS & SERVICES

Matrix MarineShield™

Wraparound corrosion protection system for pipelines, risers, and piles in harsh marine environments

Distributed Buoyancy

Lightweight, depth-rated syntactic foam modules for dynamic cables, umbilicals, and flowlines

Installation Buoyancy

Engineered buoyancy aids that support safe lifting, deployment, and positioning of subsea infrastructure

Drill Riser Buoyancy

High-strength syntactic foam modules that reduce load and improve stability in deepwater drilling

Matrix Drag & VIV Suppression

Hydrodynamic strakes and fairings that reduce vortex-induced vibration and drag on subsea structures

Protective Coatings (Humidur® FP)

Long-life, certified anti-corrosion coatings suitable for potable water and marine infrastructure applications

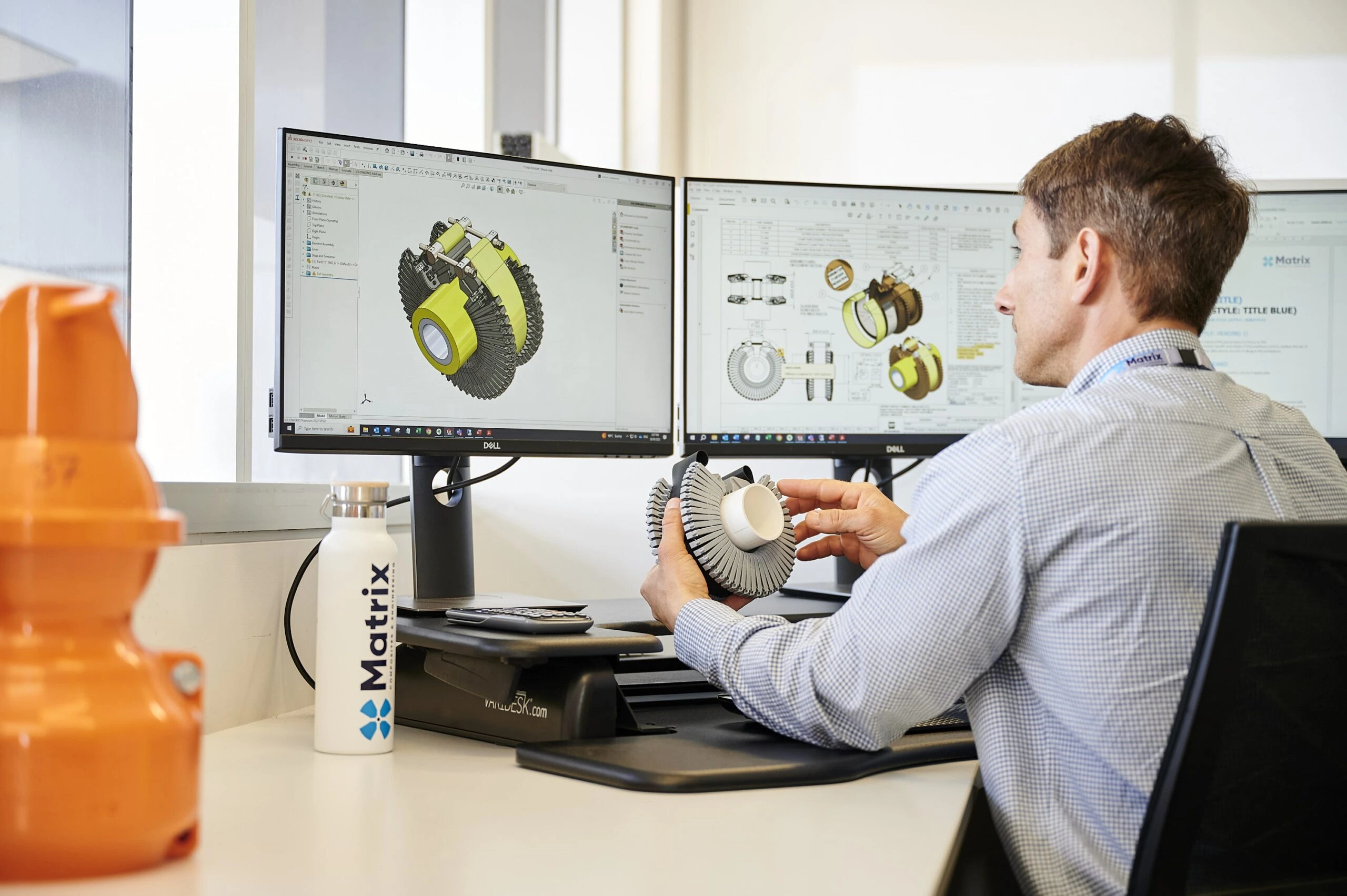

WHY CHOOSE MATRIX FOR INFRASTRUCTURE

All technologies are developed and manufactured at our Henderson facility in Western Australia, home to the world’s largest syntactic foam plant and the Southern Hemisphere’s largest subsea test centre. This full in-house capability ensures quality, reliability, and rapid delivery across every project.

Whether you’re building new marine systems or upgrading aging infrastructure, Matrix provides proven materials and support to help your assets withstand time, tides, and impact.

WHY CHOOSE MATRIX FOR INFRASTRUCTURE

All technologies are developed and manufactured at our Henderson facility in Western Australia, home to the world’s largest syntactic foam plant and the Southern Hemisphere’s largest subsea test centre. This full in-house capability ensures quality, reliability, and rapid delivery across every project.

Whether you’re building new marine systems or upgrading aging infrastructure, Matrix provides proven materials and support to help your assets withstand time, tides, and impact.

LET’S TALK INFRASTRUCTURE

Looking for corrosion protection, buoyancy systems, or low-maintenance materials for marine infrastructure? Speak with our team to Discover how Matrix can support your next coastal or subsea project with durable, high-performance solutions.

LET’S TALK INFRASTRUCTURE

Looking for corrosion protection, buoyancy systems, or low-maintenance materials for marine infrastructure? Speak with our team to Discover how Matrix can support your next coastal or subsea project with durable, high-performance solutions.