Mining

Matrix delivers advanced composite materials and protective coatings that tackle corrosion, abrasion, and impact – keeping mining operations running longer, safer, and more efficiently.

Mining

Matrix delivers advanced composite materials and protective coatings that tackle corrosion, abrasion, and impact – keeping mining operations running longer, safer, and more efficiently.

INDUSTRY CHALLENGES WE SOLVE

From pit to plant, mining environments expose infrastructure to extreme wear, corrosion, and chemical attack. Maintaining performance and safety across these conditions is an ongoing challenge. At Matrix, we understand these pressures – and we engineer material and coating solutions to help operations run longer, safer, and with fewer unplanned interruptions.

Steel Corrosion

Pipes, tanks, and walkways degrade quickly in harsh environments, but our corrosion-resistant materials deliver long-term protection.

Structural Wear

Vibration and chemical exposure weaken infrastructure, but our composite solutions restore strength while enabling fast, reliable repairs.

Slurry Damage

Slurry systems suffer extreme abrasion and chemical attack, so we use durable linings and elastomers to extend equipment life.

Surface Hazards

Slippery or degraded surfaces pose serious risks, and our anti-slip coatings improve safety across high-traffic areas.

Repair Delays

Traditional repair methods are slow and disruptive, while Matrix systems install faster and last longer to reduce unplanned downtime.

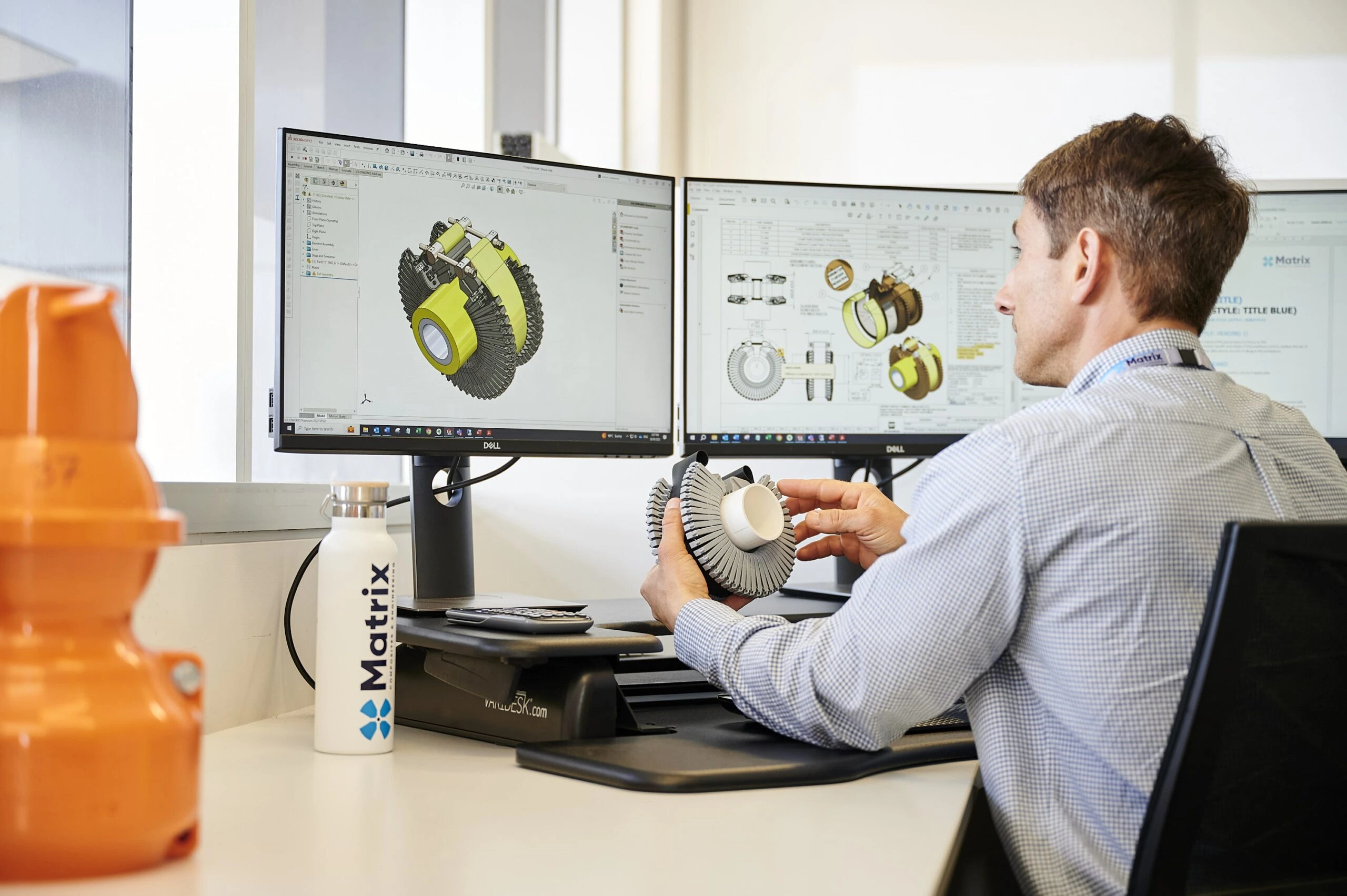

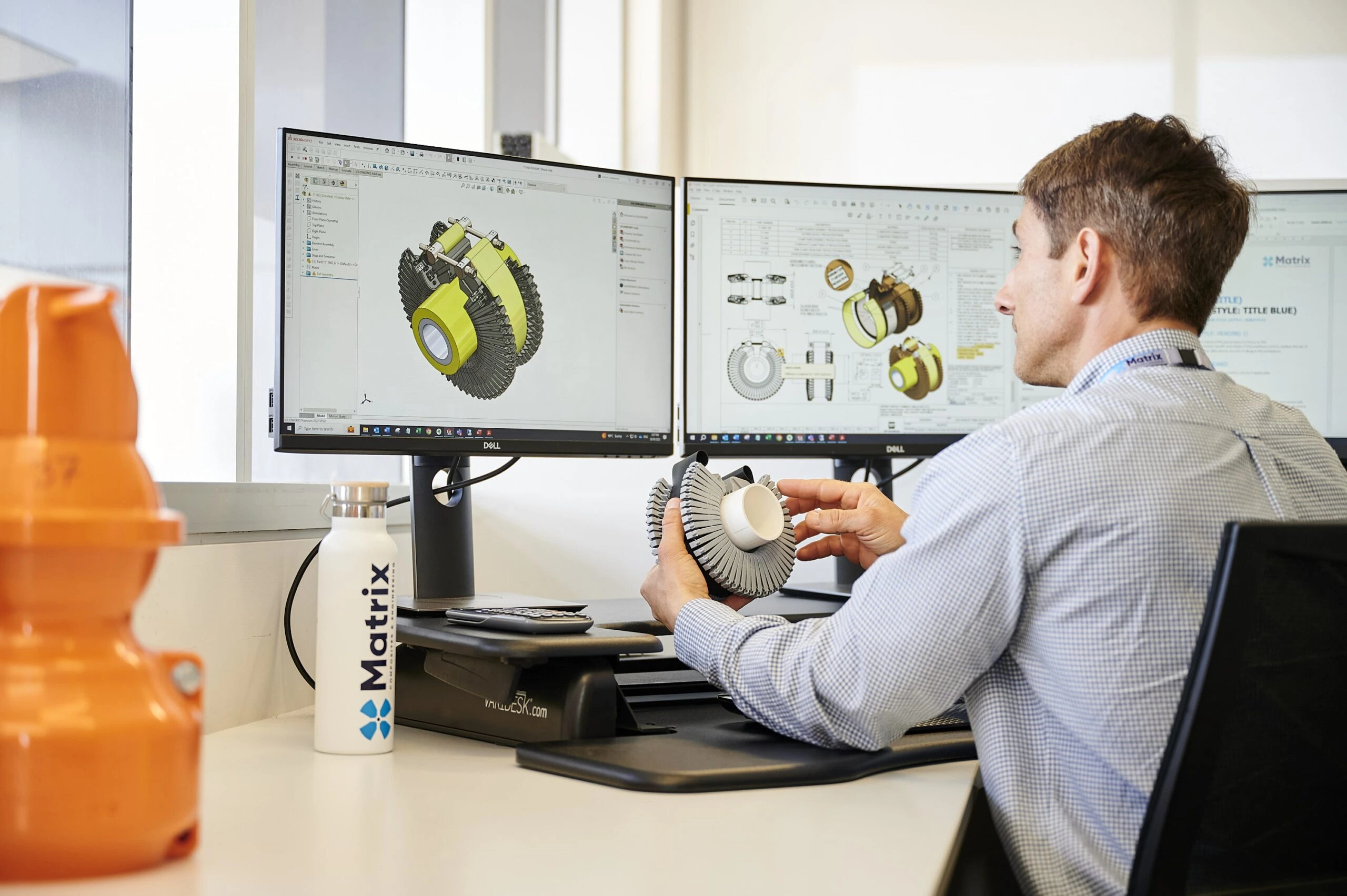

Skill Shortage

Remote sites often lack qualified repair teams, so we offer modular systems and training to enable safe, efficient on-site application.

INDUSTRY CHALLENGES WE SOLVE

From pit to plant, mining environments expose infrastructure to extreme wear, corrosion, and chemical attack. Maintaining performance and safety across these conditions is an ongoing challenge. At Matrix, we understand these pressures – and we engineer material and coating solutions to help operations run longer, safer, and with fewer unplanned interruptions.

Steel Corrosion

Pipes, tanks, and walkways degrade quickly in harsh environments, but our corrosion-resistant materials deliver long-term protection.

Structural Wear

Vibration and chemical exposure weaken infrastructure, but our composite solutions restore strength while enabling fast, reliable repairs.

Slurry Damage

Slurry systems suffer extreme abrasion and chemical attack, so we use durable linings and elastomers to extend equipment life.

Surface Hazards

Slippery or degraded surfaces pose serious risks, and our anti-slip coatings improve safety across high-traffic areas.

Repair Delays

Traditional repair methods are slow and disruptive, while Matrix systems install faster and last longer to reduce unplanned downtime.

Skill Shortage

Remote sites often lack qualified repair teams, so we offer modular systems and training to enable safe, efficient on-site application.

INDUSTRY CHALLENGES WE SOLVE

From pit to plant, mining environments expose infrastructure to extreme wear, corrosion, and chemical attack. Maintaining performance and safety across these conditions is an ongoing challenge. At Matrix, we understand these pressures – and we engineer material and coating solutions to help operations run longer, safer, and with fewer unplanned interruptions.

Steel Corrosion

Pipes, tanks, and walkways degrade quickly in harsh environments, but our corrosion-resistant materials deliver long-term protection.

Structural Wear

Vibration and chemical exposure weaken infrastructure, but our composite solutions restore strength while enabling fast, reliable repairs.

Slurry Damage

Slurry systems suffer extreme abrasion and chemical attack, so we use durable linings and elastomers to extend equipment life.

Surface Hazards

Slippery or degraded surfaces pose serious risks, and our anti-slip coatings improve safety across high-traffic areas.

Repair Delays

Traditional repair methods are slow and disruptive, while Matrix systems install faster and last longer to reduce unplanned downtime.

Skill Shortage

Remote sites often lack qualified repair teams, so we offer modular systems and training to enable safe, efficient on-site application.

COMPOSITES THAT DELIVER. LIGHTER, STRONGER, SAFER AND CORROSION-FREE

From structural repairs to chemical resistance, Matrix composites are delivering measurable results across mining operations.

ENERGY COMPONENTS EXPORTED WORLDWIDE

AUSTRALIAN MANUFACTURED

YEARS MATERIAL EXPERIENCE

HUMIDUR APPLICATORS TRAINING

COMPOSITES THAT DELIVER. LIGHTER, STRONGER, SAFER AND CORROSION-FREE

From structural repairs to chemical resistance, Matrix composites are delivering measurable results across mining operations.

ENERGY COMPONENTS EXPORTED WORLDWIDE

AUSTRALIAN MANUFACTURED

YEARS MATERIAL EXPERIENCE

HUMIDUR APPLICATORS TRAINING

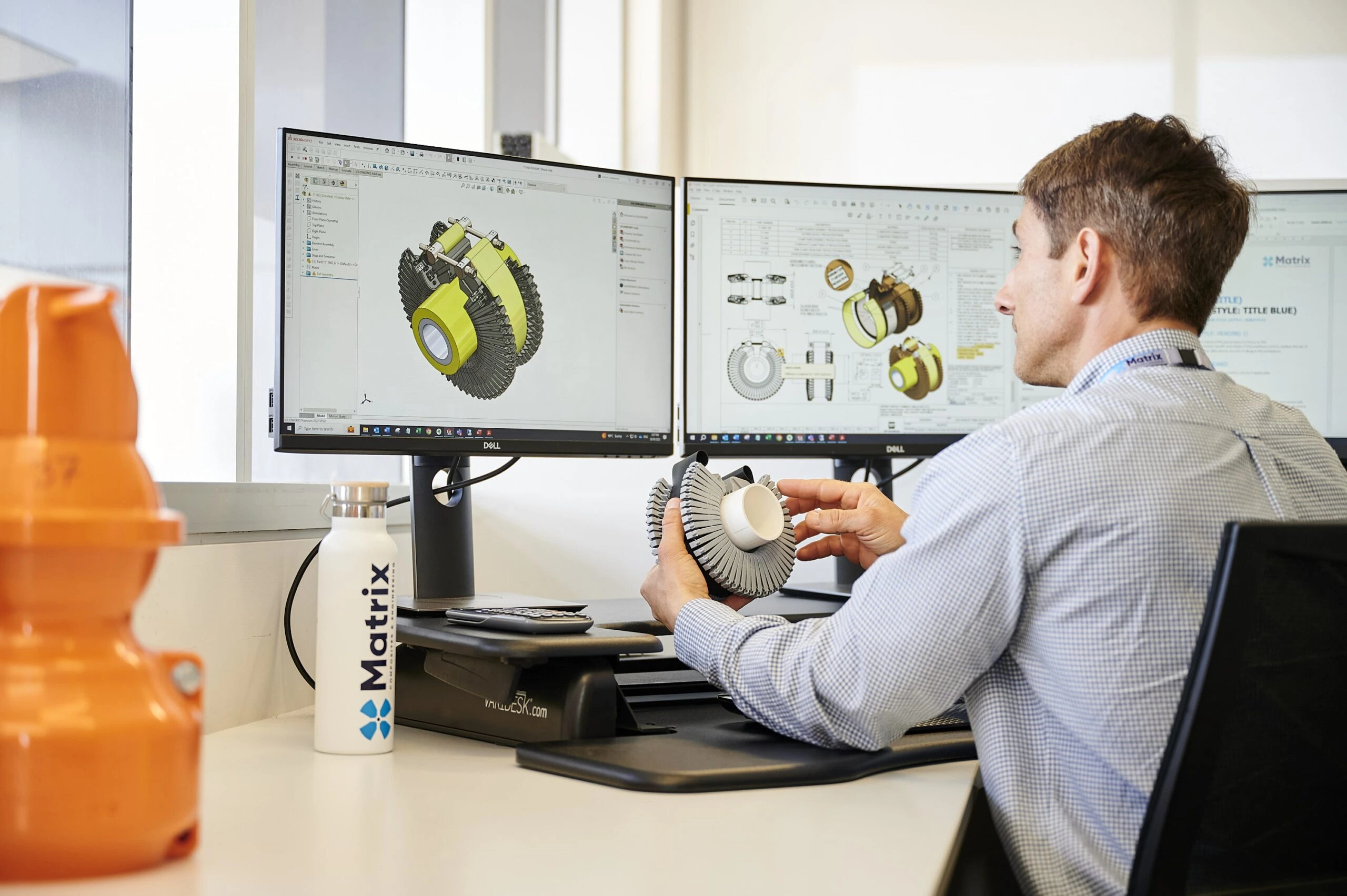

OUR CAPABILITIES IN MINING

Built for harsh environments, our composite solutions outlast traditional materials, delivering longer life while reducing environmental impact.

That performance is backed by a full suite of in-house capabilities, purpose-built to support mining operations from concept to completion:

OUR CAPABILITIES IN MINING

Built for harsh environments, our composite solutions outlast traditional materials, delivering longer life while reducing environmental impact.

That performance is backed by a full suite of in-house capabilities, purpose-built to support mining operations from concept to completion:

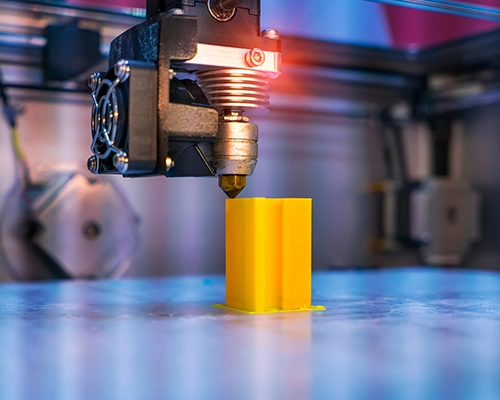

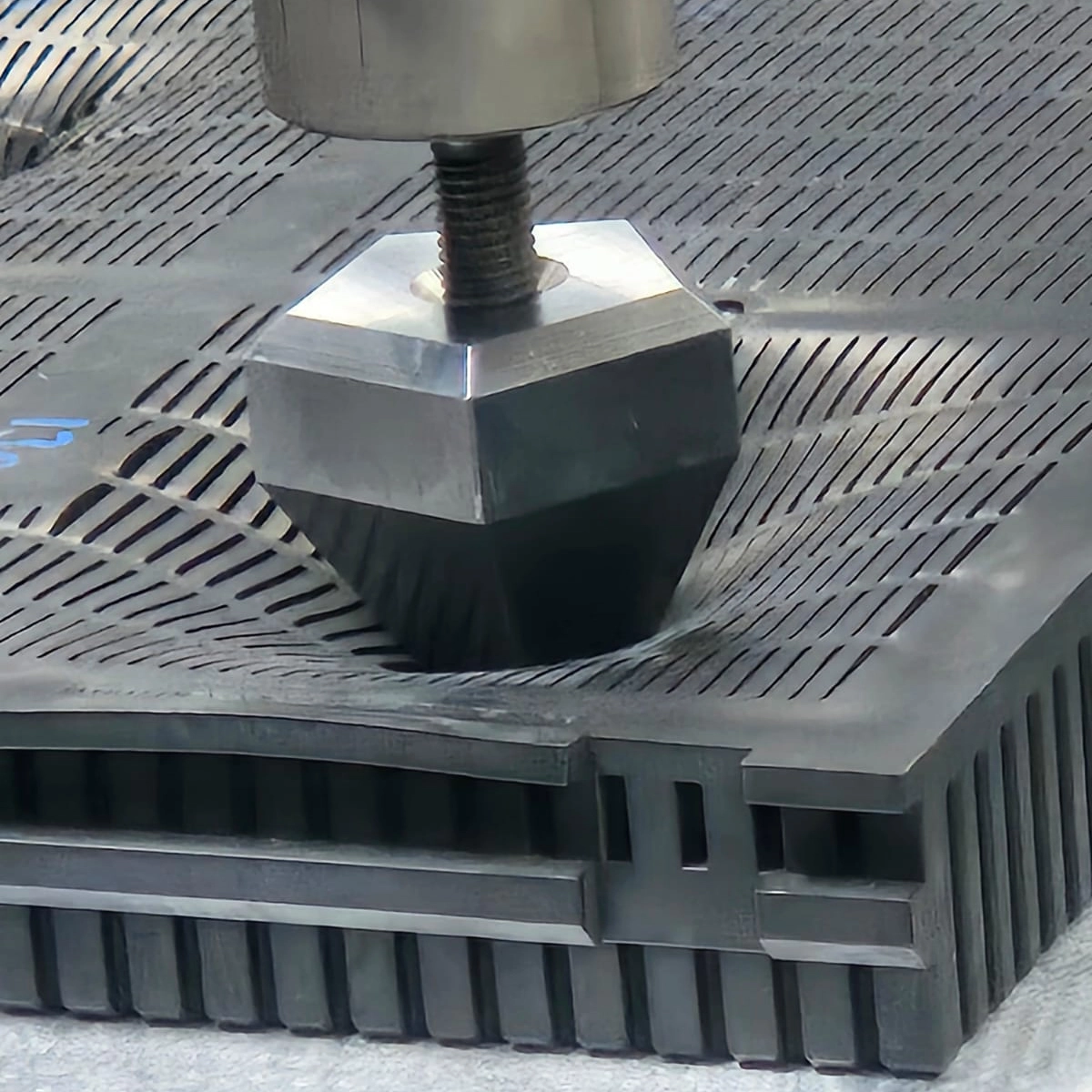

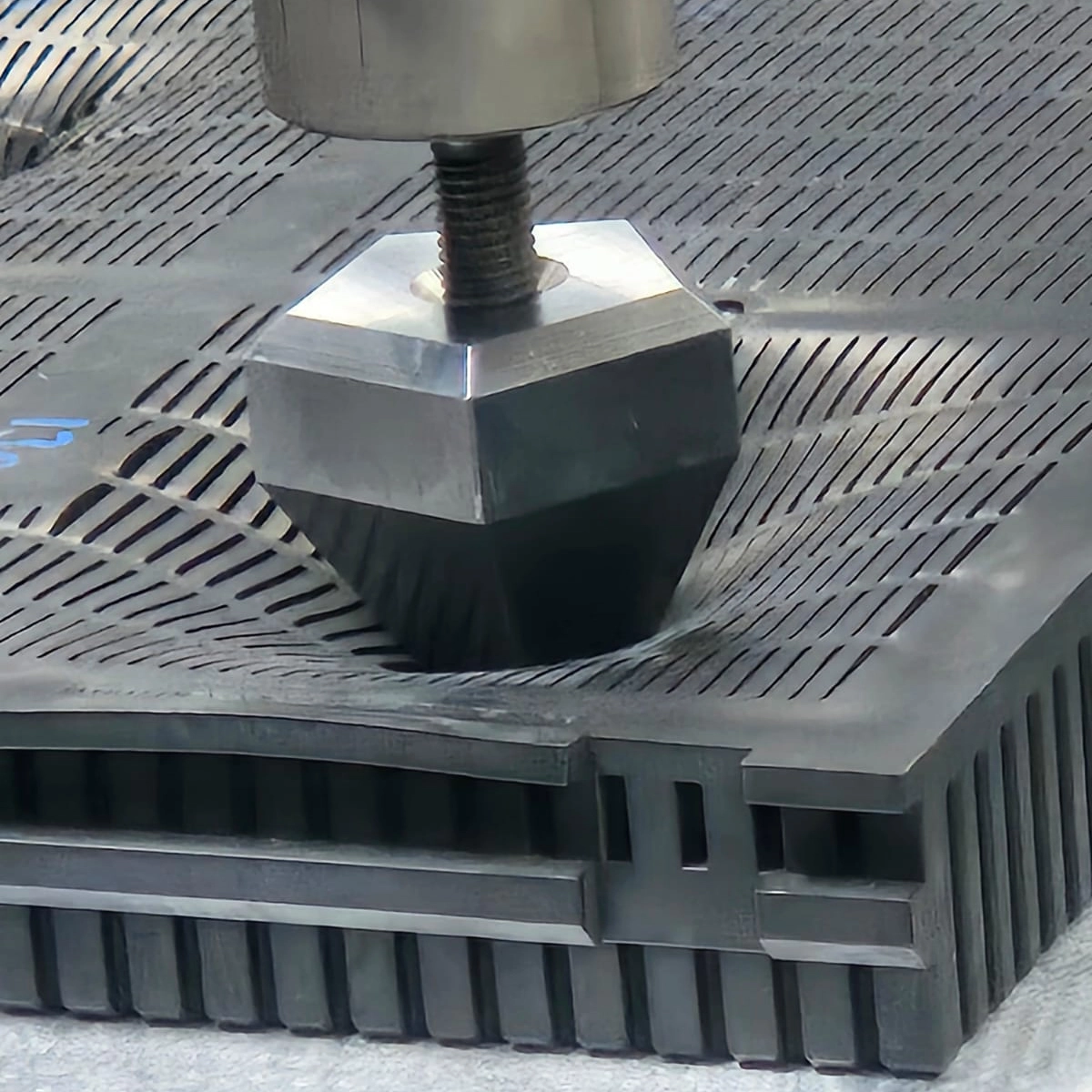

OUR MINING TECHNOLOGIES

At Matrix, we apply a range of advanced manufacturing technologies and engineered materials to solve the toughest problems in mining. These proven processes allow us to deliver solutions that are stronger, lighter, and more corrosion-resistant than traditional materials.

Carbon Fibre & Fibreglass Composites

Lightweight, corrosion-resistant materials for structural repairs.

OUR MINING TECHNOLOGIES

At Matrix, we apply a range of advanced manufacturing technologies and engineered materials to solve the toughest problems in mining. These proven processes allow us to deliver solutions that are stronger, lighter, and more corrosion-resistant than traditional materials.

Carbon Fibre & Fibreglass Composites

Lightweight, corrosion-resistant materials for structural repairs.

OUR MINING TECHNOLOGIES

At Matrix, we apply a range of advanced manufacturing technologies and engineered materials to solve the toughest problems in mining. These proven processes allow us to deliver solutions that are stronger, lighter, and more corrosion-resistant than traditional materials.

Carbon Fibre & Fibreglass Composites

Lightweight, corrosion-resistant materials for structural repairs.

Products & Services for Mining

Explore our proven products and services designed to keep mining operations running stronger, longer, and safer.

Custom Polymer Components

Injection-moulded parts designed for durability in high-wear, high-impact mining environments.

Matrix Fibrenetic

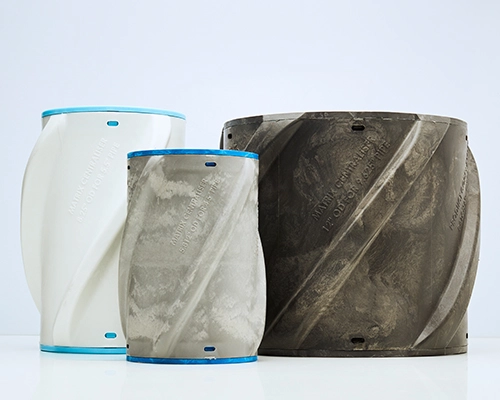

Matrix Seamless Rotolining

Abrasion- and chemical-resistant linings for tanks, pipes, and vessels

Kinetica Syntactic Foam

Impact-absorbing material for equipment protection and plant environments

Protective Coatings (Humidur® Range)

Long-life coatings for corrosion and wear protection on metal infrastructure

Applicator Training & Equipment Hire

Training and rental equipment to support safe, correct application

Products & Services for Mining

Explore our proven products and services designed to keep mining operations running stronger, longer, and safer.

Custom Polymer Components

Injection-moulded parts designed for durability in high-wear, high-impact mining environments.

Matrix Fibrenetic

Matrix Seamless Rotolining

Abrasion- and chemical-resistant linings for tanks, pipes, and vessels

Kinetica Syntactic Foam

Impact-absorbing material for equipment protection and plant environments

Protective Coatings (Humidur® Range)

Long-life coatings for corrosion and wear protection on metal infrastructure

Applicator Training & Equipment Hire

Training and rental equipment to support safe, correct application

Products & Services for Mining

Explore our proven products and services designed to keep mining operations running stronger, longer, and safer.

Custom Polymer Components

Injection-moulded parts designed for durability in high-wear, high-impact mining environments.

Matrix Fibrenetic

Matrix Seamless Rotolining

Abrasion- and chemical-resistant linings for tanks, pipes, and vessels

Kinetica Syntactic Foam

Impact-absorbing material for equipment protection and plant environments

Protective Coatings (Humidur® Range)

Long-life coatings for corrosion and wear protection on metal infrastructure

Applicator Training & Equipment Hire

Training and rental equipment to support safe, correct application

Why choose Matrix for Mining

With a strong heritage in the subsea sector, Matrix is now applying its proven materials and engineering expertise to the mining industry. Our advanced composites, protective coatings, and in-house manufacturing capabilities are built to perform in extreme environments – making them ideally suited to the operational demands of mining. From structural repairs to chemical-resistant linings, we’re helping operators extend asset life, reduce downtime, and increase safety across mine sites and processing facilities.

Why choose Matrix for Mining

With a strong heritage in the subsea sector, Matrix is now applying its proven materials and engineering expertise to the mining industry. Our advanced composites, protective coatings, and in-house manufacturing capabilities are built to perform in extreme environments – making them ideally suited to the operational demands of mining. From structural repairs to chemical-resistant linings, we’re helping operators extend asset life, reduce downtime, and increase safety across mine sites and processing facilities.

LET’S TALK MINING SOLUTIONS

Whether you need structural repairs, chemical-resistant linings, or custom-engineered components, we’re here to help. Talk to our team about how Matrix can support your mining operation with proven, high-performance materials and solutions built for the harshest conditions.

LET’S TALK MINING SOLUTIONS

Whether you need structural repairs, chemical-resistant linings, or custom-engineered components, we’re here to help. Talk to our team about how Matrix can support your mining operation with proven, high-performance materials and solutions built for the harshest conditions.

LET’S TALK MINING SOLUTIONS

Whether you need structural repairs, chemical-resistant linings, or custom-engineered components, we’re here to help. Talk to our team about how Matrix can support your mining operation with proven, high-performance materials and solutions built for the harshest conditions.