OUR TECHNOLOGIES

01

3D PRINTED STRUCTURES

Matrix uses additive manufacturing to rapidly produce lightweight, functional polymer parts with complex geometries. Engineering-grade materials enable strong, chemically resistant components suitable for brackets, housings, and custom field tools. 3D printing offers fast turnaround, minimal waste, and cost-effective prototyping or low-volume production.

02

CARBON FIBRE & FIBREGLASS COMPOSITES

Matrix designs carbon fibre and fibreglass composites for structural strength, lightweight performance, and corrosion resistance. Reinforcement fibres are arranged into tailored fibre architectures and bonded with resin systems to create high-integrity components used in infrastructure, mining, and energy. These materials are ideal for structural repair, reinforcement, and complex composite parts.

03

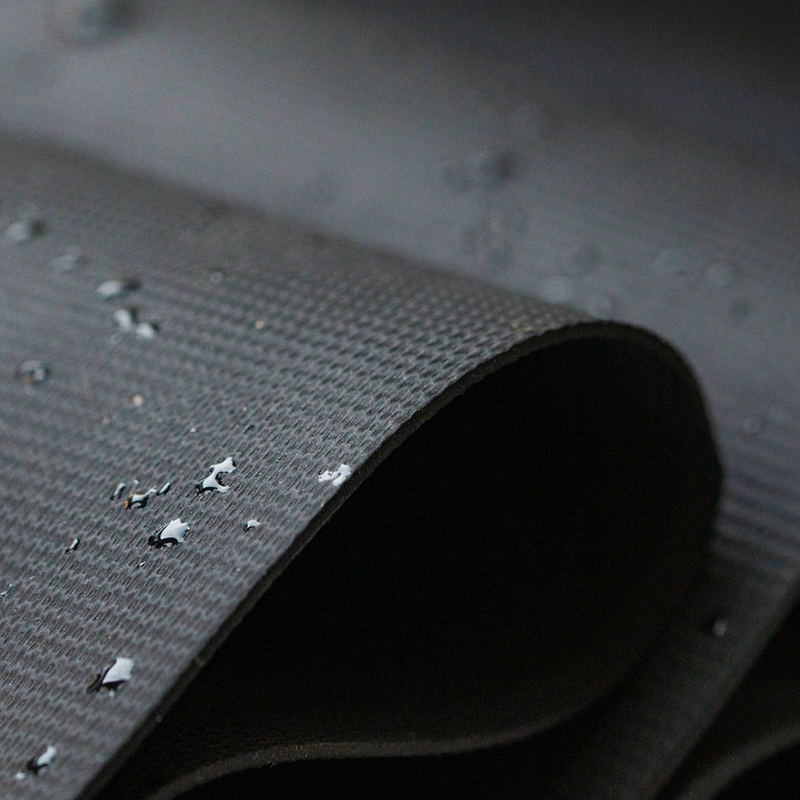

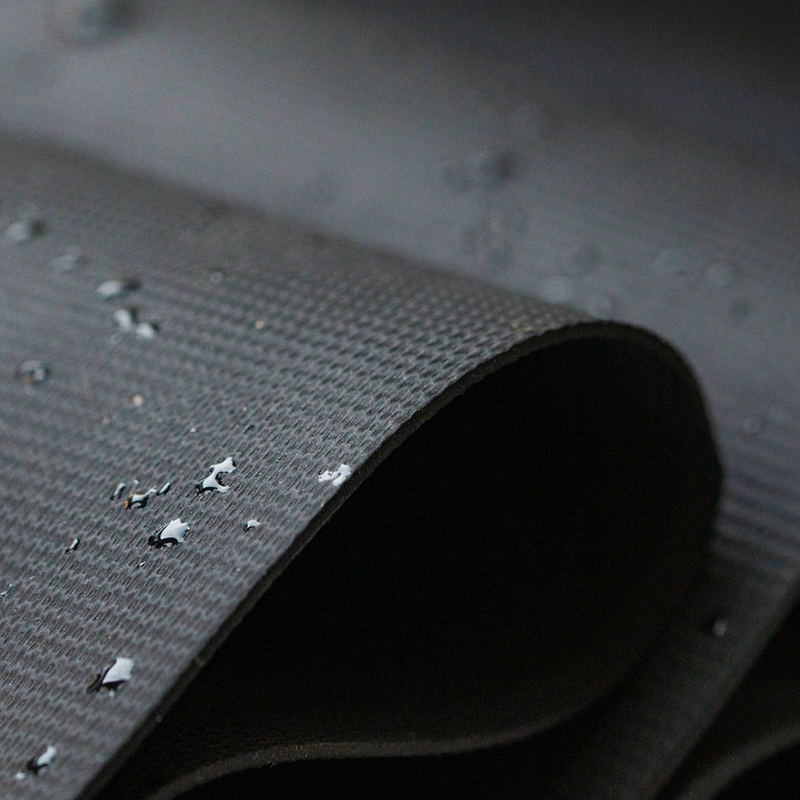

ELASTOMERS

Matrix develops polyurethane and silicone elastomers for impact protection, insulation, and wear resistance. Tailored with fibre and particulate reinforcements, these materials are custom-formulated and moulded for mining, subsea, and defence applications. Matrix elastomers provide reliable mechanical performance and flexibility where durability and resilience are critical.

ENGINEERING THERMOPLASTICS

Matrix machines high-performance thermoplastics into custom components for demanding applications. Materials like PEEK, Nylon, and PTFE are precision-cut to meet tight tolerances and chemical resistance requirements in energy, defence, and processing systems. Ideal for small-batch production, wear components, and mission-critical parts.

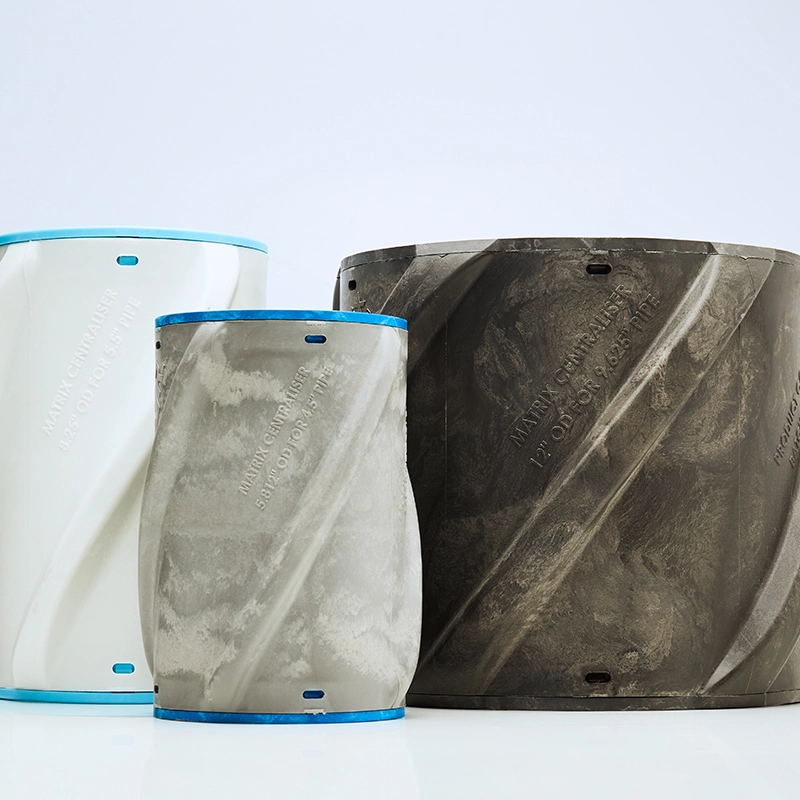

INJECTION MOULDING

Matrix produces high-precision polymer components through injection moulding, offering tight tolerances, repeatability, and strength. Reinforced engineering thermoplastics are shaped into functional parts like clamps, centralisers, and brackets for use in mining, energy, and industrial systems. Ideal for high-volume production of durable, field-ready parts.

06

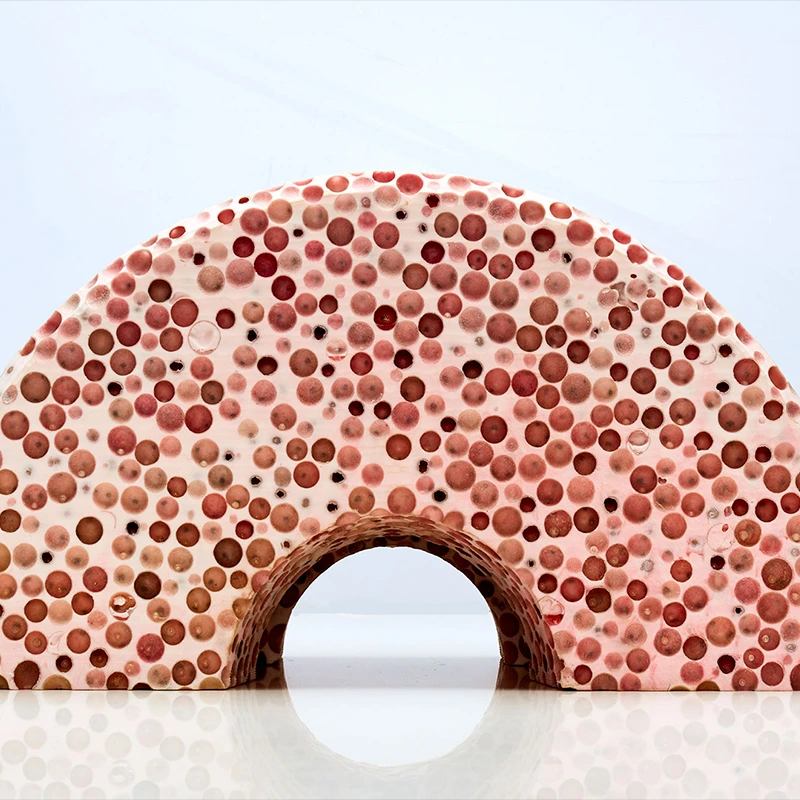

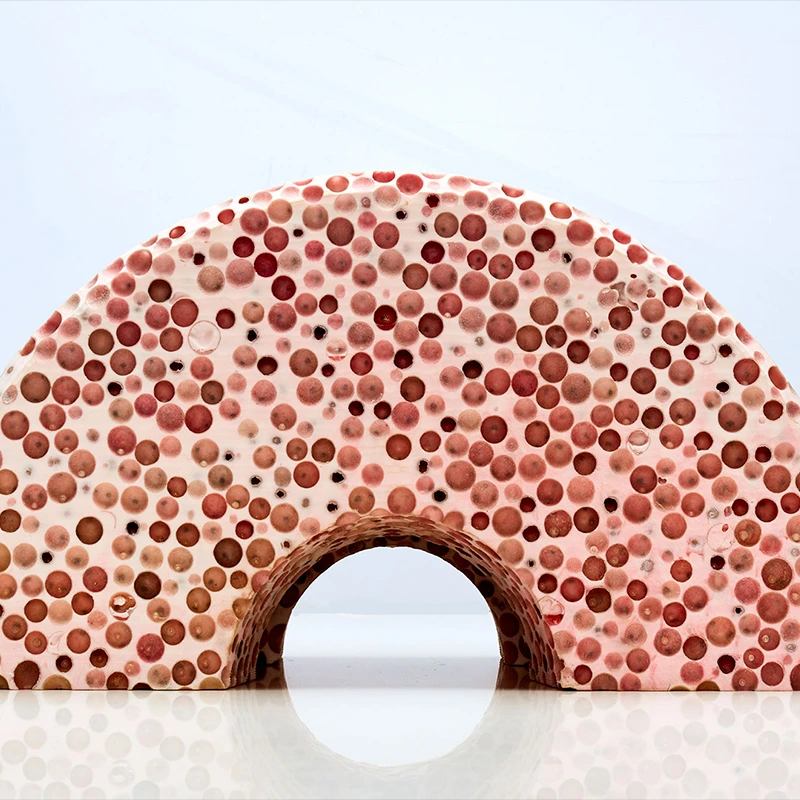

SYNTACTIC FOAM

Matrix is a world leader in syntactic foam manufacturing. These lightweight, high-strength materials are made by embedding hollow microspheres in a resin matrix to deliver buoyancy, insulation, and impact protection in subsea and industrial environments. With a proven track record in deepwater and LNG applications, Matrix syntactic foams offer strength, stability, and long-term reliability.

07

THERMOPLASTIC COMPOSITES

Matrix manufactures impact-resistant thermoplastic composites using recyclable polymers reinforced with short or continuous fibres. These materials are produced through injection moulding, vacuum consolidation, and over moulding, offering strength, durability, and lightweight performance. Used in riser covers, centralisers, and structural laminates, they provide an efficient alternative to metal in harsh operational environments.

ROTATIONAL MOULDING

Matrix uses large-scale rotational moulding to create durable, hollow polymer parts with uniform wall thickness and high impact resistance. This low-pressure, high-precision process supports the production of marine floats, barriers, housings, and structural components for infrastructure, defence, and offshore industries.

01

3D PRINTED STRUCTURES

Matrix uses additive manufacturing to rapidly produce lightweight, functional polymer parts with complex geometries. Engineering-grade materials enable strong, chemically resistant components suitable for brackets, housings, and custom field tools. 3D printing offers fast turnaround, minimal waste, and cost-effective prototyping or low-volume production.

02

CARBON FIBRE & FIBREGLASS COMPOSITES

Matrix designs carbon fibre and fibreglass composites for structural strength, lightweight performance, and corrosion resistance. Reinforcement fibres are arranged into tailored fibre architectures and bonded with resin systems to create high-integrity components used in infrastructure, mining, and energy. These materials are ideal for structural repair, reinforcement, and complex composite parts.

03

ELASTOMERS

Matrix develops polyurethane and silicone elastomers for impact protection, insulation, and wear resistance. Tailored with fibre and particulate reinforcements, these materials are custom-formulated and moulded for mining, subsea, and defence applications. Matrix elastomers provide reliable mechanical performance and flexibility where durability and resilience are critical.

04

ENGINEERING THERMOPLASTICS

Matrix machines high-performance thermoplastics into custom components for demanding applications. Materials like PEEK, Nylon, and PTFE are precision-cut to meet tight tolerances and chemical resistance requirements in energy, defence, and processing systems. Ideal for small-batch production, wear components, and mission-critical parts.

05

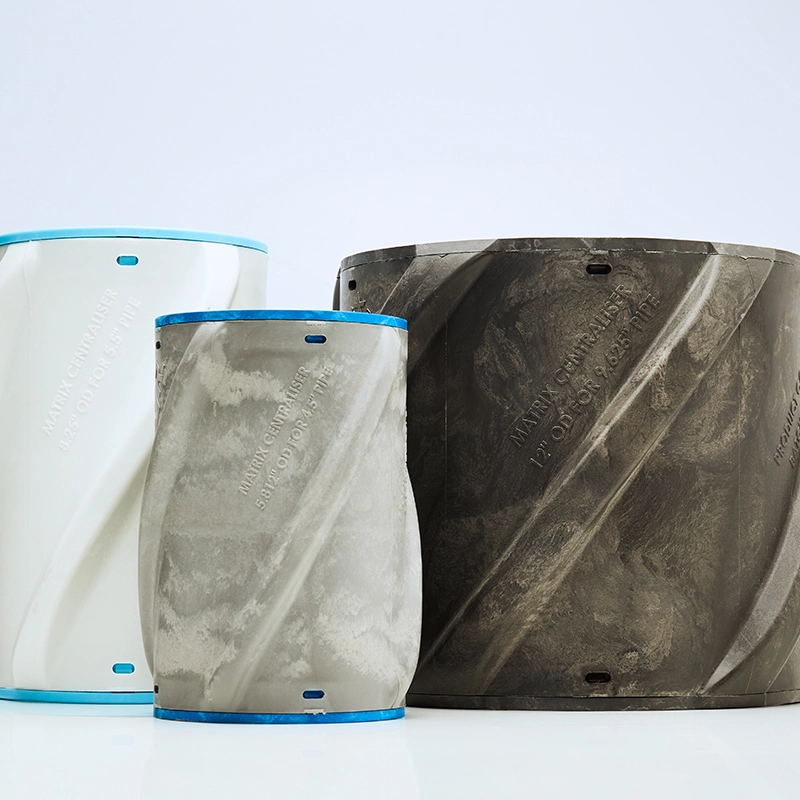

INJECTION MOULDING

Matrix produces high-precision polymer components through injection moulding, offering tight tolerances, repeatability, and strength. Reinforced engineering thermoplastics are shaped into functional parts like clamps, centralisers, and brackets for use in mining, energy, and industrial systems. Ideal for high-volume production of durable, field-ready parts.

SYNTACTIC FOAM

Matrix is a world leader in syntactic foam manufacturing. These lightweight, high-strength materials are made by embedding hollow microspheres in a resin matrix to deliver buoyancy, insulation, and impact protection in subsea and industrial environments. With a proven track record in deepwater and LNG applications, Matrix syntactic foams offer strength, stability, and long-term reliability.

THERMOPLASTIC COMPOSITES

Matrix manufactures impact-resistant thermoplastic composites using recyclable polymers reinforced with short or continuous fibres. These materials are produced through injection moulding, vacuum consolidation, and over moulding, offering strength, durability, and lightweight performance. Used in riser covers, centralisers, and structural laminates, they provide an efficient alternative to metal in harsh operational environments.

ROTATIONAL MOULDING

Matrix uses large-scale rotational moulding to create durable, hollow polymer parts with uniform wall thickness and high impact resistance. This low-pressure, high-precision process supports the production of marine floats, barriers, housings, and structural components for infrastructure, defence, and offshore industries.